Well,

finally I have cracked the

sads with the red and have taped it to move onto the black coat. Eventually, I got into a loop of not being happy with the result, sanding more, sanding through to primer, repainting, etc. Its not all perfect, but Its going to be good enough to hit with rubbing compound after I pull up the tape. It was time to boot my

OCD and just get on with it.

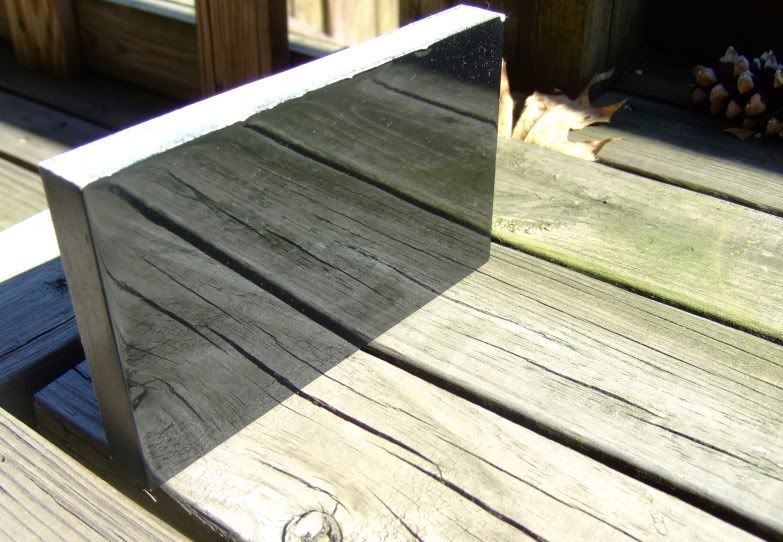

This is what

I've come up with and have started painting with. Once the black is

sprayed over that and sanded back to a flat sheen, I will pull up the blue painters tape, revealing the red below.

I have come across my arch-nemesis, water. One of the screws kept

popping up

through the red (below, screw removed) which I had to

de-bog, rip the screw out, drill the hole out bigger and re-bog. There was no choice - covering it

wasn't a option.

Also, I had some issues with swelling on some of the joints. I had gone back to primer on these bits but I though 'well, they wont be seen and will be painted black, and it

hasn't cut through to the wood, so I can keep

wetsanding'. Apparently this WAS NOT the case, and there has to have been a gap of some sort (even though these joints have been worked and re-worked more times that I care to remember). Thankfully, they have shrunk back after a day in the sun (The below pic is after shrinking - it was popped out about 5 times as much when it

happened). I suspect a hit with a rough grit, re-prime well and continue painting will fix this up. Frustrating, yes, end of the world, hopefully not.